University of Houston GURI (Texas Governor’s University Research Initiative) Lab – Energy Industry Partnerships Lab Managed under the Guidance of Prof. Ganesh Thakur, NAE, NAI

Conference Room and Visualization Lab

List of important items available for the project

- Dean-Stark Glass Distillation Assembly (Plug Size), Six-Unit (220 Volt) for extraction of water and oil by distillation from plug size core samples. Water is recovered and measured accurately in graduated receiving tubes; oil content is determined by weight loss using, optional precision balance.

- Ultra-Perm 610 Permeameter uses advanced precision mass flow meters and pressure transducers to measure absolute permeability in rock plugs with a diameter of 1″ or 1.5” and a height of around 4 cm. By combining automated data acquisition and graphics in real time, with mass flow determinations, greater accuracy and precision of the data are obtained. The instrument allows the determination of permeability in the range from 0.01 to 3,000 md. The operating software allows permeability data to be easily related to historical and current databases generated by different techniques.

- Gas Shale Matrix Permeameter (Model: SMP-200): Shale Matrix Permeameter provides a precise method for determining matrix permeability on crushed oil or gas shale samples, or drill cuttings. Utilizes GRI method with data collection up to 2,000 seconds with both “raw” and calculated data available. The range of permeability measurement: 1 Femtodarcy (10 -15 Darcy) to 1 Micro Darcy (10-6 Darcy).

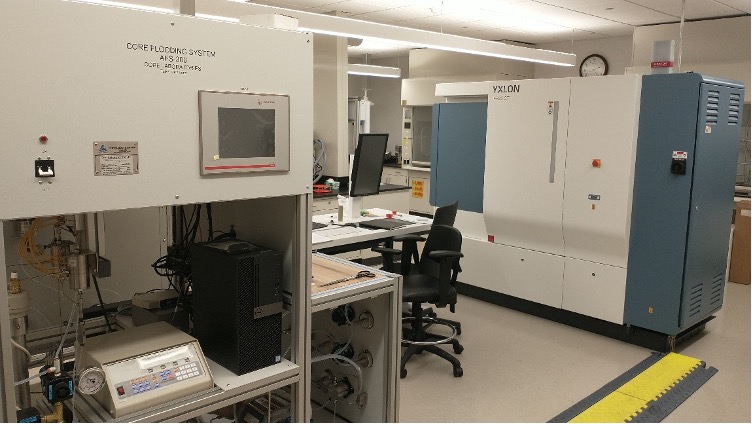

- Dual Core Flooding – Minimum Miscibility Pressure (MMP) Apparatus: The dual system provides the capability of

- core flooding test to allow absolute permeability and unsteady state (USS) relative permeability measurements in core samples, and also the determination of performance of waterflood and various EOR processes.

- MMP measurement of a reservoir fluid with a selected injection gas using the slim tube technique.

The system is comprised of an oven enclosing three injection fluid accumulators, a visual cell, an Anton Paar densitometer, a computer controlled injection pump for accurate setting of fluid injection rates, a back pressure regulation (BPR) system, a separator, and a gas measurement system. The test conditions range up to 9,500 psig pore pressure and 10,000 psig overburden pressure at maximum of 302 degF.

- Core holders designed for various test conditions: The maximum working pressure and temperature of our core holders can reach up to 10,000 psi and 300 degree Fahrenheit respectively.

- Pressure Tapped Core Holder (1.5″ dia, for polymer coreflood)

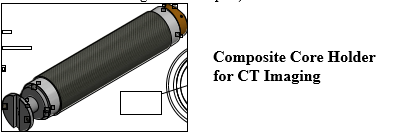

- Composite Core Holder for CT Imaging (1.5”diameter /12” length, Aluminum, Carbon Fiber and Epoxy)

- Hydrostatic Core Holders (for both 1.0” and 1.5” diameters core samples)

- Tri-axial Type Loading (CT compatible, Aluminum/Carbon Fiber Overwrap, for 1.5” diameter and max 8” length core samples)

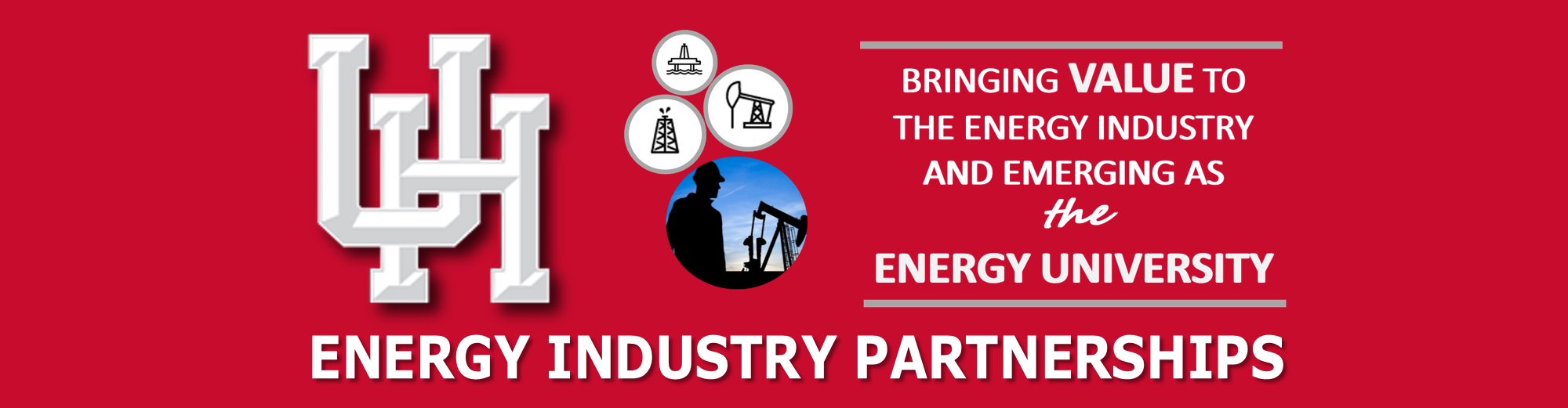

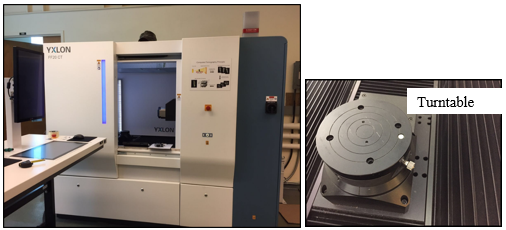

- High Resolution Industrial CT System (Model: YXLON FF-20)

- Integration of Core Flooding System with CT-Scanning capability for in-situ saturation monitoring (ISSM); the core holder is mounted to the rotating turn table.

- Digital rock study: 2D detail visibility of up to 150 nm with new water-cooled 190 kV transmission tube

- Application flexibility using trajectories such as helical CT scan, horizontal field-of-view extension, virtual rotation axis, and standard Quick/QualityScan

- Post-processing software: PerGeos (ThermoFisher)

- PVT 300/700 FV EDU system: This is for reservoir fluid phase behavior studies (PVT). Our PVT system is complete of one set of PVT instrument and some ancillary equipment, as gasmeter, HP pressure sample cylinders, viscometer, etc. It is able to analysis different GOR reservoir fluid as crude oil, volatile oil, gas condensate and gas under high pressure and temperature conditions.

This system can process the comprehensive evaluation for oil and gas reservoirs.

- Constant Compositional Expansion

- Constant Compositional Depletion

- Separator Test

- Differential Vaporization

- Fluid Envelop Phase

- Constant Volume Depletion

- Mobile Recombination Cell (Model: MRC1000): Our recombination cell is capable to recombine the surface samples of oil and gas by mixing them at specified GOR and desired reservoir pressure and temperature. Our instrument is mobile, mounted on wheels for easy movement in the laboratory. It is composed of

- – 2,000 ml cell – 1,000 bar – 200 degC

- – a motorized and manual rocking system

- – an electrical heating system with heating jacket

- – a visual window system for saturation pressure observation

- – a temperature and pressure display panel

- – a set of valves, fittings, pressure gauge

- Gasometer with cooling trap for PVT (Model: GAS4000): Manual gasometer 4L – GAS4000. This equipment is composed of following elements :

- Absolute Linear Encoder

- Automatic Moving Piston under 0.2 bar over pressure

- 2 Manual Valves

- Handle Adjusting Piston Position at standard pressure

- Calibrated Glass Tube

- Absolute Pressure sensors

All wetted parts are made of Stainless Steel (ref SS316) except the tube (Glass) and the piston (Gas Resistant Plastic)